As a core transmission component in automation systems, ball screw modules are widely used in automated equipment, 3D printers, CNC machine tools, and other precision machinery. They are valued for their high accuracy, high rigidity, and long service life. However, once accuracy degradation occurs during operation, it can directly affect the stability of machining, assembly, and positioning processes. After long-term use, issues such as mechanical wear and lubrication failure often lead to a decline in precision. So how can such problems be identified quickly? The following methods can help determine whether the accuracy of a ball screw module has deteriorated.

Using a laser interferometer or a high-precision linear encoder, command the module to perform multiple positioning movements across its full stroke. Compare the actual positions reached with the theoretical commanded positions, and evaluate the dispersion when returning repeatedly to the same location. If the positioning deviation or repeatability error exceeds the allowable tolerance of the equipment, it is a clear indication of accuracy degradation.

Run the ball screw module at low speed under no-load conditions and carefully listen for abnormal sounds. Modules with reduced accuracy often exhibit noticeable vibration, unusual noise, or crawling motion due to ball wear, lead error of the screw, or increased clearance in the guide rails. These phenomena are direct signs of deterioration in the transmission components.

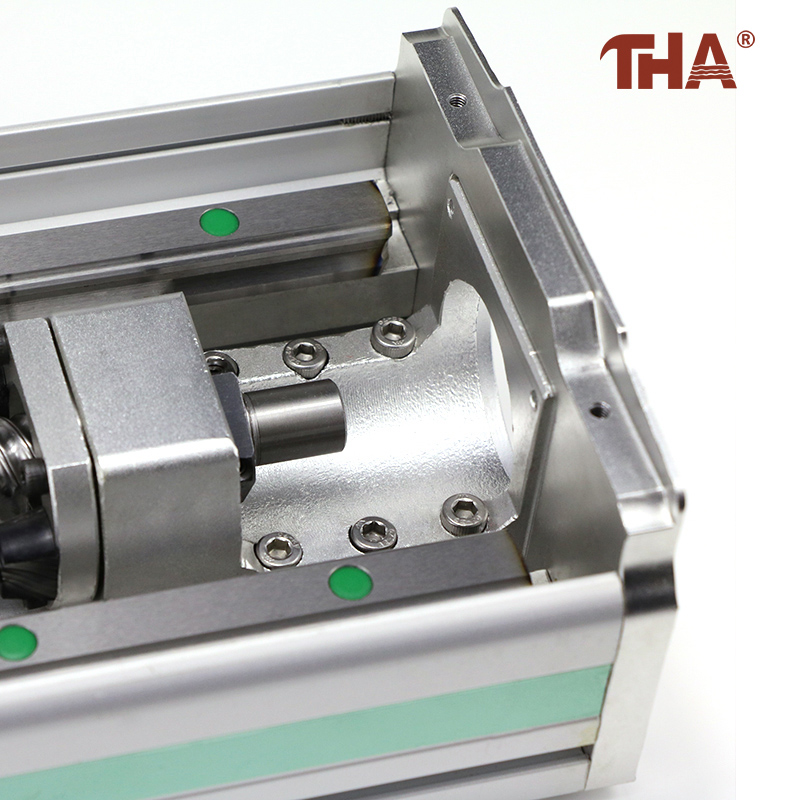

After stopping the machine, inspect the surface of the ball screw for signs of wear, indentations, corrosion, or insufficient lubrication. Manually rotate the screw and feel whether the resistance is smooth and uniform. A healthy ball screw module should rotate smoothly with consistent resistance. Any sticking, uneven torque, or localized tight spots indicate defects that may lead to precision loss.

Maintaining the accuracy of ball screw modules is a long-term process where prevention is always better than correction. By regularly monitoring key indicators such as backlash and repeat positioning accuracy, and by applying proper lubrication and maintenance practices, the service life of the module can be effectively extended while ensuring stable, efficient operation of the equipment.

Whatsapp/wechat:17769815516/18967093658

Email: tha@gyballscrew.com

gykristyliu@gmail.com

sales@gyballscrew.com